Cidect 5BL/5BI: Static behaviour of joints made of thin walled hot/cold formed hollow sections

Introduction

Joints made of very thin-walled hollow sections can be used in light structures, such as green-houses, framed structures, gables, secondary structures and trusses (see Fig. 1.1). Using structures made of very thin-walled hollow sections will clearly provide appropriate weight reductions. There are also big advantages in transportation and erection costs.

Fig. 1.1: Example green-house

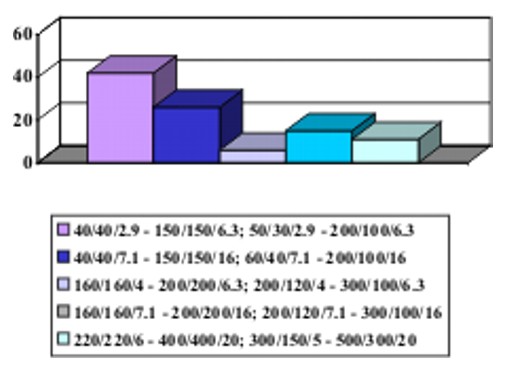

That there is a real important market for those thin-walled hollow sections is shown on Fig. 1.2. This diagram gives the distribution of constructional hollow sections in dependence of the dimensions of the sections in the German market. It can clearly be seen that more than 40% of the whole production are sections with wall thickness t < 6.3 mm.

Cold- and hot-rolled hollow sections.

Distribution in percent

Fig. 1.2: Distribution of hollow sections (German market) in percent by weight

There has been a lot of research work in the area of the static behaviour of hollow section joints made of RHS. However, there is only limited information available on the static strength behaviour of such joints made of very thin-walled members. Nearly all tests on the static and fatigue behaviour of joints made of square hollow sections are made of members with wall-thicknesses t > 4 mm. Regarding the relevant design recommendations such as Eurocode 3, CIDECT design guides and IIW recommendations no guidance is given for these very thin-walled connections.

With special regard to these sections, it is possible that there might be an influence on the static properties (local buckling, stiffness effects, weld influence, thickness influence, etc.) for wall-thicknesses below 4 mm.

In the current research programme it is planned to verify the static behaviour of these types of joints. With some typical static tests on T-, X-, Y- and K gap - joints with different t1/t0, b1/b0 and b0/t0 ratios it will be checked whether the existing rules can be used for joints with member wall-thicknesses t < 4 mm.

The first part of the programme consists of a literature study. Existing test results are allocated and it is checked how these results fit together with the actual design recommendations given in the CIDECT Design Guide for RHS joints under predominantly static loading.

In the second part of the work static tests on T-, X-, Y- and K-Joints with gap are carried out. In total, 13 pilot tests have been planned. In a special test rig the joints will be loaded by a single jack. The results are compared with the CIDECT Design Recommendations and other rules found in the literature study.