|

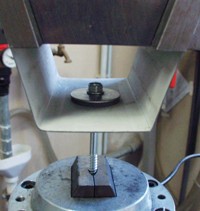

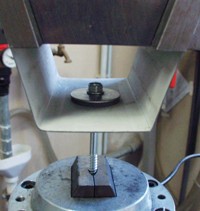

Within the scope of this project, reduction factors were determined that allow a safe/secure design with carrying capacities, determined from stirrup samples.

The distance’s influence on non-stiffened rims was examined, too. The results for sandwich elements with PUR- or PIR foam cores can be summed up in the following way:

- The test results of stirrup samples are conservative and thereby the hithero existing certification is not justified. This is valid only if for the analyses Z-14.4.407 fwb= 0,67 or less is assumed.

The end-bearing’s punching carrying stability generally accounts 80% of the intermediate-bearing’s punching carrying stability. This is caused by the fact that the torsion of the end-tangent of sandwich elements with bigger plate diameters only a part of the percentage contact area of the core layer can be activated. This effect is independent of the edge distance e1. The reduction of the bearing capacity is barely covered by the hithero existing certification. A concluding statement is not possible, due to missing experiments with repeatedly stressed end-bearings.

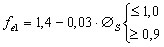

- For edge distances of 20mm ≤ e1 ≤45mm, the punching carrying capacity is to be reduced by a factor of :

whereas the plate diameter S[mm] is to be inserted. This factor considers the tearing to the free edge. For smaller edge distances no statement is possible.

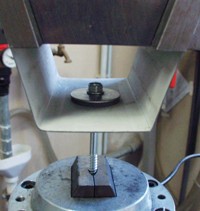

- For roof panels with top boom fastening without calotte it is only permitted to calculate with 50% of the results of the punching carrying capacity

- The experiments run on roof panels with top boom fastening without a foam core show that for trapezoid profiles it is also permitted to calculate with only 50% of the results. For sandwich elements with mineral cotton the results are, generalized, regarding the punching carrying capacity not as good as the ones for sandwich elements with PUR or PIR core layers.

back |

|