Design of fatigue-stressed building parts made of high- and ultra-high strength fine grained steels in crane and plant construction

- contact:

Dipl.-Ing. Jennifer Hrabowski

Dr.-Ing. Stefan Herion

- project group:

- funding:

FOSTA

Abstract:

The European regulations for designing crane- and conveyor systems are written in EN 13001 “Krane – Konstruktion allgemein”. The regulations for crane runways and crane-substructures are defined in the Eurocodes. The action is regulated in EN 1991, part 3 “Einwirkungen infolge Kranen und Maschinen”. The resistances are to be calculated according to EN 1993, part 6 „Kranbahnen“. A clear separation of crane and crane substructures is not always possible due to the interaction of both systems. This means that it is necessary to work with groups of standards. Neither the detail categories of EN 13001, nor the ones of ENV or EN 1993 cover all destruction details for cranes and conveyor systems. In those cases, conservative approximations have to be done, which can lead to uneconomical constructions. But it is not only the construction details that are not mentioned/regarded in the current standards, high- and ultra-high strength fine-grained steels are not mentioned as well.

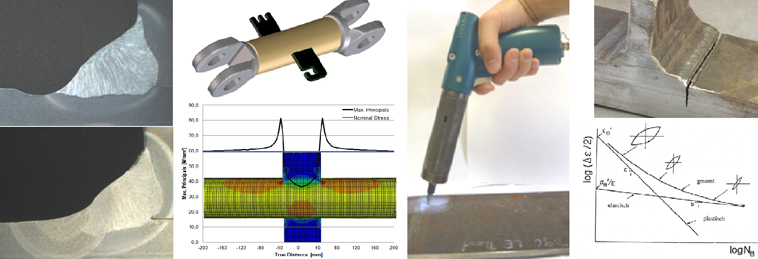

New concepts of design and propositions to judge the fatigue behaviour of welded constructions, from mechanical engineering and plant construction, allow a more detailed consideration of relevant parameters. As an example, the material- , construction- and the building part characteristics can be mentioned.

Within the scope of this project, the capability of these new design/designing concepts in crane- and plant construction shall be checked. If necessary, accordant modifications are to be worked out, which allow reliable designing with those concepts. For this purpose, existing results from previous research projects will be complemented and extended. Also new series of tests will be planned and run.

So a more specific and realistic evaluation of characteristic groove details in crane constructions made of high- and ultra-high strength steels will be made, which will lead to a more cost-effective use of those steels as well as an improvement of the capability of cranes with the same weight.

This project is to be understood as a continuance of the previous assignments. Based on these projects and the state of the art technology, experimental data and the most current developments in the area of designing concepts shall be contrasted with this project. The assignments will be complemented with fatigue tests, run wit S1300 and two new groove details.

The results will be processed according to the standards and shall be integrated directly into the rules and standards. This will be assured by the enrolee’s memberships in the accordant international boards/bodies. By active co-operation of crane manufacturers at the production of samples, as well as the application and evaluation of different designing methods, a praxis-oriented proceeding is guaranteed.

The expected results of this project conduce to reach a higher utilization of high- and ultra-high strength materials. Because of the reduced construction weight, the reduced plate thickness and the related reduced welding effort, an improvement of the ecological balance sheet of crane- and conveyor systems as well as an improvement of the subconstructions will be reached for designing with the new European standards.

Research partners:

Lehrstuhl für Stahlbau und Leichtmetallbau, RWTH Aachen

Lehrstuhl für Stahl- und Leichtmetallbau, Fachhochschule München

Industry partners:

Demag Cranes & Components GmbH

Dillinger Hütte GTS

Faun GmbH

Gottwald Port Technology GmbH

Ilsenburger Grobblech GmbH

Kranbau Köthen GmbH

Liebherr Werk Biberach GmbH

Liebherr Werk Ehingen GmbH

SSAB Oxelösund AB

Terex-Demag GmbH&Co.KG

ThyssenKrupp Steel AG

V&M Deutschland GmbH

Voestalpine Grobblech GmbH