Experimental assays

|

Experimental assays:Extensive fatigue tests are currently run to verify the effectiveness of high-frequency methods. The groove details butt weld and welded braces are to be examined. Specific parameter variations shall document the influence of steel quality, levels of load, plate thickness, overloading and the scale of assays. Additionally, extensive measurements are done that allow conclusions about the influence of the after-treatment methods to the cracking behavior. The fatigue tests are run in servohydraulic and resonance testing machines.

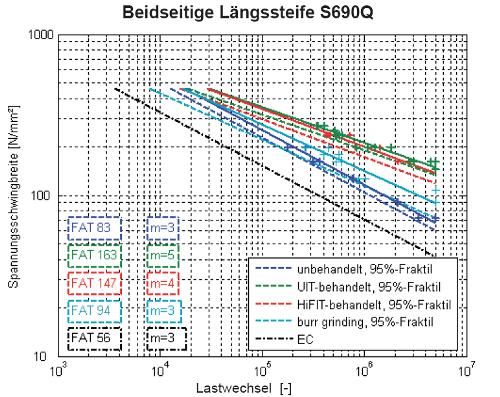

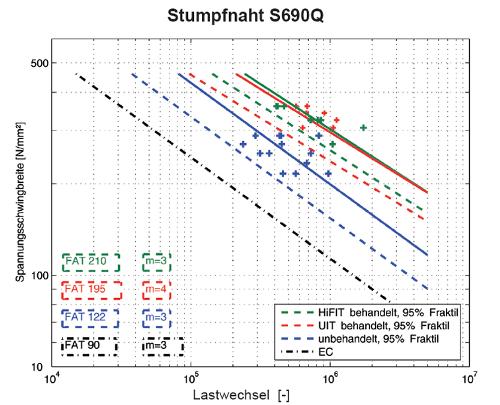

Experimental results:The first results of the fatigue tests show that the fatigue strength can be significantly increased by the after treatment with high-frequency hammering methods. First results show that the fatigue strength of butt and longitudinal samples made of S690 can be doubled. For the butt sample an increase of the groove classification to 190 (UIT method) and to 210 (HiFIT method) were proofed. After HiFIT treatment, fractures mostly appeared in the base material.The crack origin of bilateral longitudinal braces with fillet welds shifts from the seam transition to the radix. Here, the fatigue strength was doubled with both methods.

|

|